Chris Thompson USyd Lectures Listing Anaesthetic Machines - VAPOURISERS Physical Concepts

Saturated Vapour Pressure (SVP) - partial pressure of the vapour phase of a substance when at equilibrium with its liquid phase (e.g. in a closed container). Increases rapidly as boiling point approaches. Boiling Point - temperature at which SVP equals ambient pressure. Desflurane boils at 23.5°C - very near room temperature. Latent Heat of Vapourisation - heat energy required to convert a given volume of liquid to a vapour while keeping both at the same temperature (kJ/kg or J/g). Approx.. 40 cal/g for volatile agents. Specific Heat - energy required to raise the temperature of a substance by 1°K. For water this is 1cal/g/°K. Thermal Conductivity - speed with which heat flows through a substance; Cu > Al > brass > steel >> glass. Volumes percent - percentage concentration of gas in a mixture; e.g. 100 * (partial pressure / total pressure). Plenum - a chamber at higher than atmospheric pressure, for distribution purposes. In-circuit vapourisers have resistance in the bypass limb, pressurising the vapour chamber relative to the outlet.

Fraction Diverted - the proportion of Fresh Gas entering the vapourising chamber. Volume vapourised - approximately 200 ml vapour per ml of liquid anaesthetic ml liquid used/hour ≈ % x FGF in l/min x 3, i.e. 2% Sevo at 1 l/min uses about 6ml of liquid per hour. Pumping effect - pulsatile back-pressure increases output, especially obvious with older vapourisers, at low flows, and with large pressure swings. Increasing back-pressure will compress gas in the plenum chamber. When the back-pressure drops, vapour-laden gas in the chamber will re-expand and try to get out. It can get out via either the inlet or the outlet line. Via the inlet line, fully-saturated gas can mix with and contaminate the bypass gas. If there is a short connection between the vapour chamber and the outlet line, pumping back and forth between the two will also increase output. Modern vapourisers have overcome this with smaller vapourising chambers and long inlet and outlet lines. Pressurising effect - (constant) backpressure reduces output. For example, high resistance in the line after the vapouriser will compress all gas before it. This increases the ratio of carrier molecules relative to vapour molecules in the vapour chamber, because the number of vapour molecules is fixed, whereas at higher pressures there will be more carrier gas molecules. The absolute percentage of agent per unit volume leaving the vapouriser is correct, but when the gas mixture expands post-obstruction, there are fewer molecules of agent per volume of carrier than there should be. This is a minor effect.

Fundamentals The operator adjusts the fraction of the total fresh gas that is diverted into the vapourising chamber. Typically only a small percentage of the total fresh gas flow enters the chamber. Gas entering the vapourising chamber is always fully saturated by the time it leaves. Vapour molecules added to the gas molecules entering the chamber increase the volume of gas leaving. The extent of this increase in volume and the amount of vapour picked up per ml of gas entering depends on volatility of the agent in proportion to atmospheric pressure. Halothane, with an SVP of 243mmHg (or about 1/3 of an atmosphere) will vapourise in the chamber until at equilibrium there will 2 parts carrier to 1 part halothane. Every 2 ml of incoming gas picks up 1 ml of vapour. For Halothane, the fraction diverted into the vapour chamber is approximately 2% when delivering 1%. The amount of volatile added, as a fraction of the incoming fresh gas flow, is therefore: Volatile added as fraction of FGF = Fraction_diverted * (SVP / (PBar-SVP)) For halothane, the factor (SVP / (PBar-SVP)) is 243/517, or about half. Hence the amount of vapour added, as a percentage of the incoming fresh gas flow, is about a half of the percentage diverted into the vapouriser. The volume leaving the vapouriser is increased by the small amount of vapour added. The be exact, the added vapour percentage should be reduced by the factor 1 / (1+ percentage vapour added). For halothane, if 2% is diverted at a barometric pressure of 760mmHg, 0.94% vapour will added in terms of incoming fresh gas flow, and the exact output percentage would be 0.93% after correcting for the vapour volume that was added. An exact formula is: Output Percentage = SVP * Fraction_diverted / (PBar + SVP*(Fraction_diverted - 1)) * 100 Thanks to David Young for correcting the incorrect formula that appeared here previously. The fraction diverted is sometimes expressed as the 'splitting ratio', ie the ratio of the amount bypassed to the amount that goes through the vapouriser. If the fraction diverted is 2%, the splitting ratio is 50:1. Sevo and Enflurane are less volatile (SVP approx.. 1/4 of an atmosphere). They require a greater fraction diverted (3 parts in to pick up 1 part of vapour). Additionally, Sevo is about 1/3 the potency of Halothane. To deliver 1 MAC Sevo in a Sevo vapouriser requires about 5 times as much flow through the vapourising chamber than 1MAC Halothane in a Halothane vapouriser. Desflurane could be used in a 'normal' vapouriser (fraction diverted at 1MAC = 0.9%) but if the room temp went up, or the barometric pressure went down, it would boil and the output would be uncontrollable. Commercial Desflurane vapourisers are heated above boiling point and release 100% vapour in a controlled manner. I've made an excel spreadsheet that calculates fraction diverted by MAC and dial setting and shows how output varies at altitude. A summary appears in the table below: Table 1 - Fraction diverted and effects of altitude

Effect of Altitude For classical plenum vapourisers, the percentage output increases roughly in proportion to the fall in barometric pressure, but a smaller partial pressure increase. Depth of anaesthesia depends on partial pressure, and the changes in partial pressure are relatively small, so normal vapouriser settings work as expected at altitude For example, a Sevoflurane vapouriser used at 8000 feet will deliver about 10% more in partial pressure terms, but 50% more in percentage terms, than expected for the dial setting. Most volatile agent monitors measure partial pressure and display this as a Sea Level equivalent percentage. In this sense the numbers displayed indicate 'anaesthetic effect' and require no mental 'correction' for altitude. If you are working at altitude you should confirm how the monitor operates as they are not all the same. The TEC 6 Desflurane vapouriser behaves differently. The percentage delivered is essentially held constant, so partial pressure FALLS in proportion to the fall in atmospheric pressure. The dial setting should be turned up to compensate The Aladdin Cassette system can be programmed to deliver either constant partial pressure output or constant pressure output. For a very detailed mathematical approach (from which the above calculations were derived), download Steve Shafer's "How Vapourisers Work". Prof. Kam's point form notes on volatile uptake provide a more general overview.

Classification of Vapourisers:

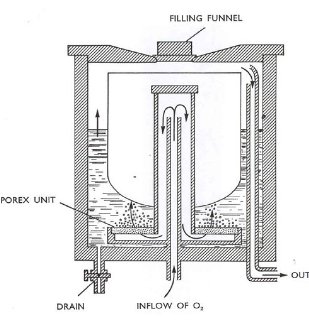

Copper, measured flow, bubble through, out of circuit, not temperature compensated, non agent specific, manually metered flow vapouriser with temperature gauge. Oxygen is bubbled through the vapour chamber from a dedicated accurate low flow rotameter and the fully saturated vapour then enters the circuit. Correct inflow can be determined from agent-specific tables that relate temperature, desired percentage output and FGF. For Halothane and Isoflurane, at 20°C: Inflow (ml/min) ≈ FGF * 20 * %.

Inflow (ml/min) ≈ FGF * 30 * %. For example, lets say you want 1% halothane at 6l/min: Inflow ≈ 6*1*20 ≈ 120ml/min The inflow of 120ml expands to 180 ml after picking up 60ml of vapour. The reason it picks up 60ml of vapour is that the partial pressure for Halothane and Isoflurane is about 1/3 of an atmosphere, so fully saturated output will always comprise 2/3 carrier (120ml) and 1/3 halothane (60ml). The total outlet flow of the vapouriser will be FGF + added vapour volume, i.e. 6000+60 = 6060 ml. Output will therefore be 60ml halothane in 6060 ml total volume or 1% (approx..). Note that the Fraction Diverted is about 2% (120ml/6000ml) when delivering 1%. Because Sevo is about 1/3 the potency of Halothane as well as being less volatile, delivering 1MAC Sevo requires about 5 times as much flow into the vapourising chamber compared to a Halothane vapouriser at 1MAC. Intrinsically dangerous because output must be manually changed whenever FGF is changed; failure to do so can lead to over or under-dosage. Useful as a teaching tool; the Aladdin cassette system works (basically) on the same principle. Further reading: see Steve Shafer's "How Vapourisers Work" and Prof. Kam's notes on volatile uptake

Variable bypass, incomplete vapourisation, flow-over without wicks, low resistance in-circuit, non-agent-specific (but intended for Halothane), no temperature compensation, no interlocks. Glass bowl marked AC Delco; originally an automotive fuel filter chamber. Economical if taken from place to place (unused agent can be put back in the bottle, no wicks. Used in-circuit. Output decreased due to cooling after induction. Patient hyperventilation if light caused increased output. Mk1 in 1959 with easily bumped 3 position levers, Mk2 in 1962 changed lever to click.

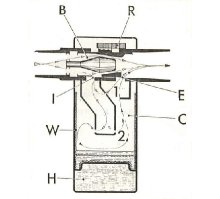

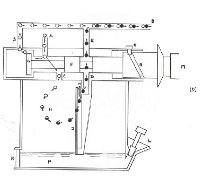

Two versions, one for Ether (with bubble-through) and one for Halothane (without) Variable bypass, incomplete vapourisation, bubble through or flow-over without wicks, low resistance in-circuit, non-agent-specific (but intended for Halothane or Ether), no temperature compensation, no interlocks Usually mounted on backbars. EMO Epstein Macintosh Oxford. 1953. Variable bypass, incomplete vapourisation, flow-over without wicks, low resistance, agent-specific for Ether, temperature compensated by bellows, temperature stabilised by water jacket, transportable but heavy (10kg). . For more information see this review of drawover anaesthetic apparatus. OMV Oxford Miniature Vapouriser. Variable bypass, flow-over with metal mesh wicks, low resistance, multiple agents, not temperature compensated, light weight. Chamber only contains 50ml of agent. Cooling limits maximum output to 2-4% with halothane. Two units in series required for a Sevo induction. Intended for field use. Can be used in series with a Laerdahl type self-inflating bag in the field or in series with an EMO for halothane inductions.

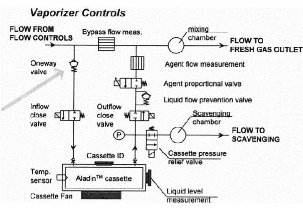

Aladdin Cassette

Can deliver partial pressure or true% depending on software settings. A fan blows warm air over the cassette if its temperature falls below 18 degrees, as may happen with gaseous inductions (Sevo or Des). The cassette includes magnets to ID the agent to the machine on insertion, an electrical connection to an internal temperature sensor, and self-sealing ports for gas in and out, but no other electronics. It is tippable and robust. More info. With Desflurane, the pressure inside the canister may exceed the inflow line pressure, at which point the inflow control valve and one-way must close firmly, and the unit functions as a pressurised injector. Partial failure of one or both of these valves may be associated with high levels of desflurane in the circuit.

Tec 6 Desflurane Outputs between 1% and 18% from 200 to 10000 ml/min FGF.

The solution was quite ingenious. A resistance in the bypass line increases upstream pressure. As a result, 'upstream' pressure increases in proportion to FGF. This pressure is monitored by a differential pressure transducer that controls an electronic flow control valve so that the 'output' pressure of the vapourising chamber is always equal to the pressure in the fresh gas inlet line. If FGF increases, both the bypass line pressure and the vapour line pressure will therefore increase to the same extent. The manually operated mechanical splitting valve on the top of the vapouriser only has to set the resistance ratio between fresh gas and vapour to set the output concentration (just like it does in any other vapouriser). NB: output in partial pressure terms diminishes with altitude. This is because the 'thinner' fresh gas flows more freely past the resistance, reducing the measured 'upstream' pressure for any given flow, which in turn reduces the vapouriser outlet pressure and hence number of molecules. The TEC 6 can be considered a true '%' generator, not a 'kPa' generator, at the outlet. Link to GE PDF.

Key Fillers

Interlocks When more than one vapouriser is attached to the backbar, the interlock system should allow only one to be on at a time. Usually this is a simple mechanical device. ANZCA policy T3 mandates vapouriser interlocks. Sequence of non-interlocked vapourisers

The classical sequence is as follows: The potential hazard is overdose on induction. It can only happen when non-interlocked vapourisers are used. Clinically significant effects require:

When a downstream vapouriser containing a mixture of agents is turned on, it will deliver its normal agent at the dial setting plus some of the dissolved agent. If the dissolved agent is more volatile and/or more potent than the normal agent, and if the dial setting is high, the net effect could be delivery of a greater anaesthetic effect than intended. Note that accumulation of dissolved agent stops at partial pressure equilibrium with the upstream vapouriser. This means that the partial pressure driving the dissolved agent out of the contaminated downstream vapouriser is usually very low indeed. Let's consider two examples: 1. An Isoflurane vapouriser contaminated with 2% Sevoflurane is set to 1MAC. The fraction diverted into the Isoflurane vapour chamber, from the preceding table, is 2.4%. The Sevoflurane vapour pressure in the vapour chamber is 15kPa. The output of Sevo would be 2.4 percent of 15mmHg, i.e. 0.36 mmHg or 0.05% - a clinically irrelevant amount of Sevoflurane. 2. A Sevoflurane vapouriser contaminated with 10% Desflurane has been set to 1MAC. The fraction diverted is 8%. The partial pressure of dissolved 10% Desflurane is 76mmHg. The output of Desflurane would be 8 percent of 76mmHg, or 6 mmHg or 0.8% Desflurane. Adding the Desflurane can at most add only about 10% to the final anaesthetic agent effect. Actually the dissolved Desflurane 'dilutes' the Sevoflurane appreciably and the net effect may be almost none. 3. A Sevoflurane vapouriser contaminated with 1% Halothane has been set to 1MAC. The fraction diverted is 8%. The partial pressure of dissolved 1% Halothane is 7.6mmHg. The output of Halothane will be 8 percent of 7.6mmHg, or 0.6 mmHg or 0.08% Halothane. This admixture only adds about 12% to the net anaesthetic agent effect. These examples show that the effect of admixtures is trivial with all modern agents. None the less, the order should be: Methoxyflurane ⇒ Sevo / Enflurane ⇒ Isoflurane / Halothane ⇒ Desflurane Sevo and Enflurane are similar in volatility, but Sevo is slightly less potent. If a Sevo vapouriser was accidentally filled entirely with Enflurane, and set to 2%, it would deliver 2% Enflurane, a relatively small overdose considering the difference in potency(about 20%). In reverse, an Enflurane vapouriser filled with Sevoflurane would tend to underdose by only about 20%. A 50-50 mixture of the two would halve these effects. Cross-contamination with small amounts <5% of the other agent would be clinically irrelevant, but the effect is minimised if the less potent agent comes first. Similarly, an Isoflurane vapouriser accidentally filled entirely with Halothane would deliver the correct percentage output, but because Halothane is about 40% more potent this would be a relative overdose. Once again, cross-contamination between the two at the percentages clinically used would not be clinically important. It follows that the impact of cross-contamination due to the absence of interlocks is small so long as methoxyflurane is first and desflurane last. Modern multi-agent auto-identifying volatile agent monitors reduce the risk even further. Selectatec-type mountings Vapourisers 'stand' on a pair of vertical pins, one for the gas inlet and one for the outlet. Each pin has an O-ring at the base that makes the seal with the vapouriser. If the O-ring fails, or the vapouriser fails to sit properly on it, there will be a backbar leak. Each pin also has a central self-sealing hole, and when the vapouriser control knob is turned, a pair of pins on the vapouriser pushes down, opening the seal below.

Vapouriser leaks Even a small leak at the outlet from a vapouriser can result in preferential loss of anaesthetic agent from the circuit causing awareness. A proper backbar leak test should detect O-ring failures even if the vapouriser is 'off'. A leak within a selectatec-mounted vapouriser, e.g. an open filler port, will not be detected by pressurising the backbar unless the vapouriser is switched on. Cross-threading the filler cap is a common cause of vapouriser leakage. Desflurane vapourisers should be secured so that traction on the power cord will not pull sideways on the vapouriser, lifting it off the O-ring and causing a backbar leak.

See Also: Equipment notes by Mark Finnis |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Goldman

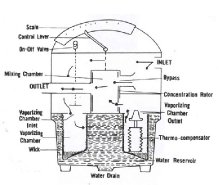

Goldman Boyles Bottle

Boyles Bottle

Like all calibrated variable bypass TEC vapourisers, the Desflurane TEC 6 has a manually operated mechanical variable-resistance proportioning valve on the top of the unit, and a resistance in the bypass line. The clever bit was how to make it work reliably, knowing that Desflurane can boil so close to room temperature. The vapour chamber is heated to 39°C to maintain a constant vapour pressure of 1500mmHg (approx... 2 atmospheres).

Like all calibrated variable bypass TEC vapourisers, the Desflurane TEC 6 has a manually operated mechanical variable-resistance proportioning valve on the top of the unit, and a resistance in the bypass line. The clever bit was how to make it work reliably, knowing that Desflurane can boil so close to room temperature. The vapour chamber is heated to 39°C to maintain a constant vapour pressure of 1500mmHg (approx... 2 atmospheres).